Comparison of Olive Oil Production Processes

Water Use and Its Effect on Wastewater Formation

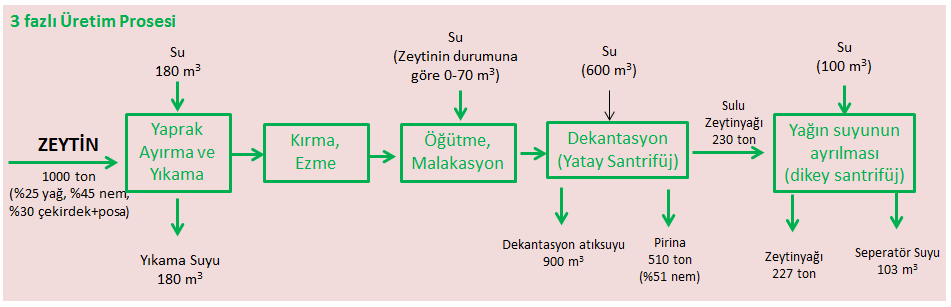

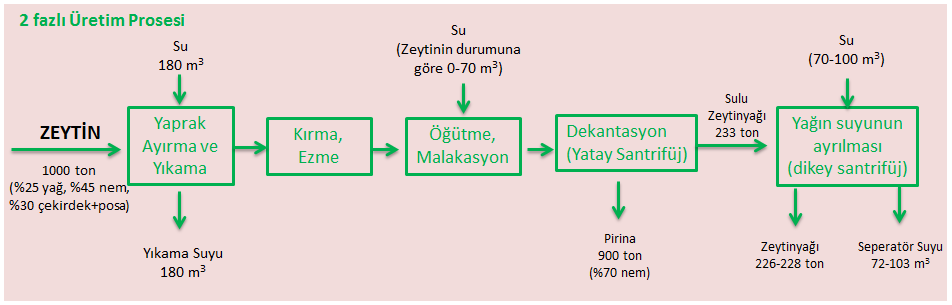

In the 3-phase production process, while 3 separate phases are formed, namely decantation wastewater, pomace and oil; In the 2-phase production process, 2 separate phases are formed, namely water pomace and oil. In 3-phase production, water is added to the decanter and this water takes some of the olive juice and leaves the system as black water. In 2-phase production, there is no water addition to the decanter and the olive juice remains in the pomace. The products and wastewater amounts formed according to the production processes are shown schematically on the figure below.

Figure 2 Olive oil production by production process

The amount of water used in olive oil production, the amount of wastewater generated and its characterization vary according to the production process. According to this;

Average in 3-phase production for the processing of 1000 tons of olives;

- - Total water usage is approximately 880-950 m3,

- - The amount of wastewater is approximately 1200 m3 (washing + decanter + separator wastewater).

Average in 2-phase production for the processing of 1000 tons of olives;

- - Total water usage is approximately 250-350m3,

- - The amount of wastewater is approximately 250-280 m3 (washing + separator wastewater).

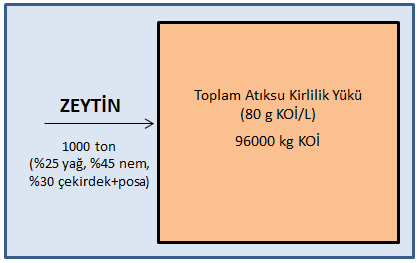

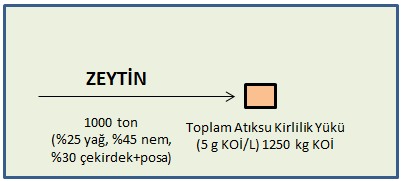

Comparison of the pollution load in the wastewater generated in the 3-phase and 2-phase production processes in the case of processing 1000 tons of olives is shown schematically below.

As a result of the processing of 1000 tons of olives, the pollution load of the wastewater generated in the 3-phase production is 96.000 kg, while the wastewater pollution load in the 2-phase system is only 1,250 kg of COD. It is seen that there is approximately 70-80 times difference between the two production processes in terms of pollution loads. The 2-phase production system is a much more environmentally friendly production method, not only in terms of the amount of wastewater, but also in terms of wastewater pollution load.

a) |

b) |

Figure 3. Wastewater pollution loads in olive oil production processes a) 3-phase production process b) 2-phase production process

Effect on Product Quality

Since water is added to the decanter in the 3-phase production system, most of the phenolic compounds pass into the decanter wastewater. However, in the 2-phase production system, most of the phenolic compounds remain in the olive oil, since there is no outside water entry. When both production processes are compared in terms of product quality, it has been shown in many studies that olive oil produced in the 2-phase system is richer in polyphenols.

Comparison of 2-phase and 3-phase production is summarized in the table below.

Table 1 Comparison of three-phase and two-phase production processes

Production Process | Advantages | Disadvantages |

3 phase |

|

|

2 phase |

|

|